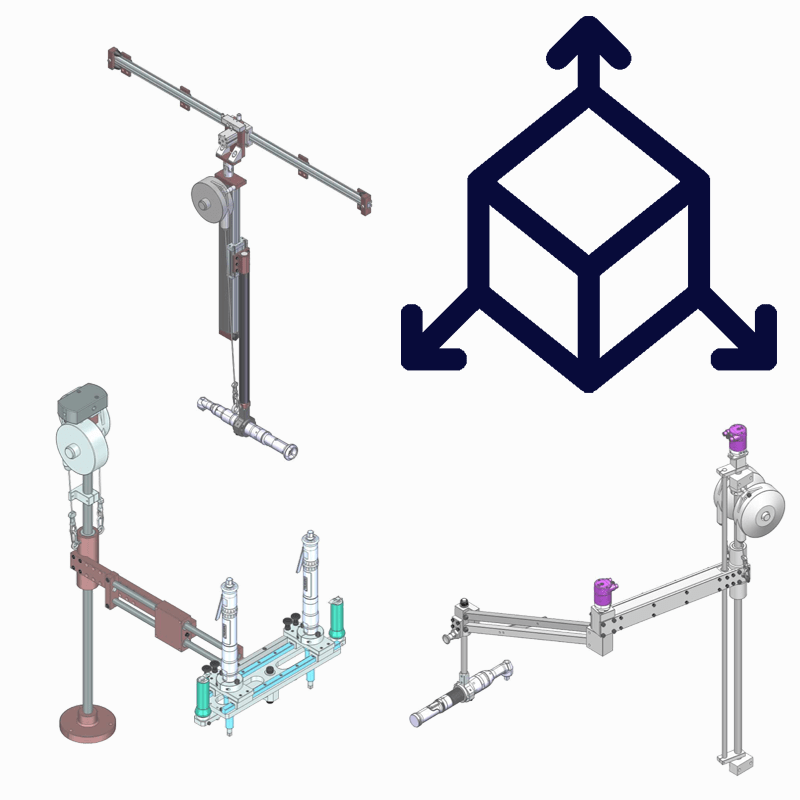

CELPRO | Taylor-made torque reaction arms

CELPRO | Taylor-made torque reaction arms

Arms with adapted geometry according to the applications and working environment.

Resources

Application sheet - Blind engine support tightening - DOC.60358

Engine support tightening at 270Nm wtih limited access & visibility.

Torque reaction arm allowing the operator to work with a good visibility and in an ergonomic position.

Application sheet - Complete tightening workstation with in line transducerized tools - DOC.60422

Accurate tightening in vertical and horizontal position of a loom angle.

Download the file in pdf

Application sheet - Helicoil insert mounting - DOC.60420

Workstation for Helicoil inserts mounting with positionning control.

Download the file in pdf

Application sheet - High torque fastening on mobile aerial lift - DOC.60319

Assembly of aerial lift components at 225 Nm and 66 Nm without reaction bar. Operator visual guidance required during assembly operations.

Download the file in pdf

Application sheet - High torque tightening - DOC.60362

Assembly optimization in terms of quality and ergonomic for high torque (400Nm).

To be able to make different assemblies with high torque and a controlled process, by replacing pneumatic

tightening tools and various torque bars.

Application sheet - Multi torque tightening workstation - DOC.60410

To tighten M6 to M12 screws at various torques from 38,4 to 210 Nm.

Download the file in pdf

Application sheet - Realand front axle tightening underframe - DOC.60399

Tightening of real axle under frame, torque 1000 Nm.

Difficult access environment.

To replace home-made arm to improve ergonomy & safety.

Application sheet - Road sign tightening - DOC.60401

To be able to achieve tightening of 5 screws with a screwdriver positionning assistance device for the operator. Specific torque reaction arm with adjustable stop to help the operator, screwdriver with automatic screwfeeding.

Download the file in pdf

Application sheet - Screwing trolley with slide - DOC.60361

Multi-disc plow frame assembly under difficult access conditions with a tightening torque at 90Nm to improve

screw tightening quality and ergonomy.

Application sheet - Tightening station in profile with screwfeeding systems - DOC.60456

Integrated customised screw-feed kit for fasteners assemblies on profiles with difficult access to tightening positions and automatic screw feeding systems.

Download the file in pdf

Application sheet - Tightening workstation of firing pin - DOC.60412

Tightening of firing pins on pyrotechnic grenade at 2 Nm.

Download the file in pdf

Application sheet - Truck understructure assembly station - DOC.60423

Tightening and torque reaction device covering a 6.5 meter radius with access to the tightening points located between 500 and 1300 mm from the ground with a vertical and horizontal tightening axis and a 360° rotation possible around the vertical axis.

Download the file in pdf

Application sheet - Upper rear shock absorber under body - DOC.60370

To tighten 2 difficult access bolts upright at 35 Nm and warrant the comfort of the operator.

Download the file in pdf