Wireless DC tools

Our products for Wireless DC tools

Main feature

- Digital torque and angle program in 15 presets and 2 multi step sequence programs

- Models with assignable tightening strategies, batch counting and logical I/O management

- Auto speed setting by torque

- Monitoring fastening quality and count of screw numbers (with Paramon Pro X interface)

- Error information by code display

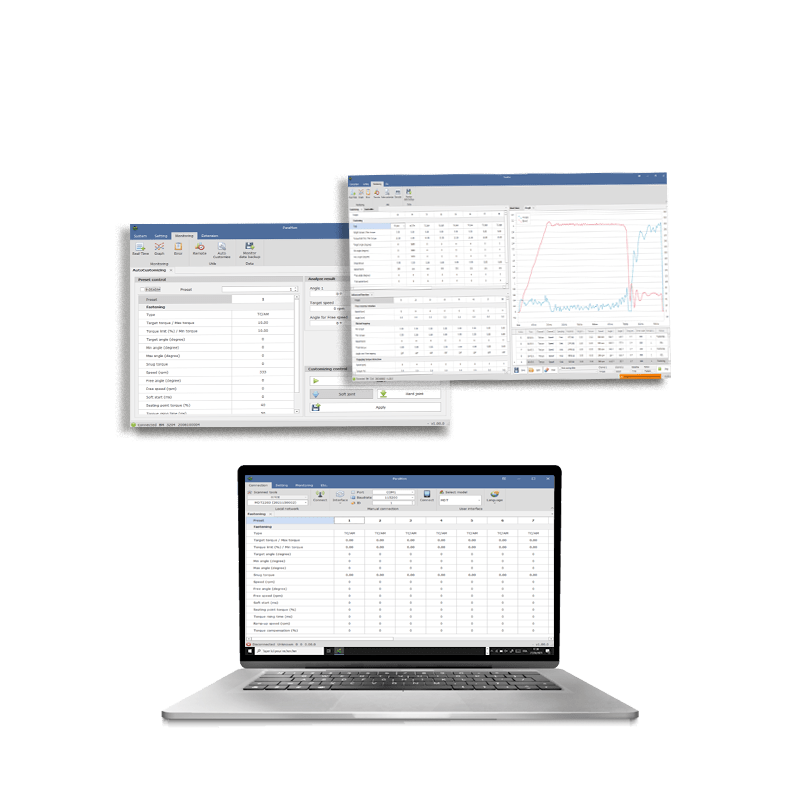

- Easy parameter setting and monitoring with ParaMon (free PC software) & built-in Web server

- Real time torque data and curve display on PC software

- Real time fastening data output by USB and Wi-fi

- Modbus protocol

- Free speed fonction to optimize cycle time

- Integrated barcode scanner for automatic preset selection and tightening results traceability (depending on model)

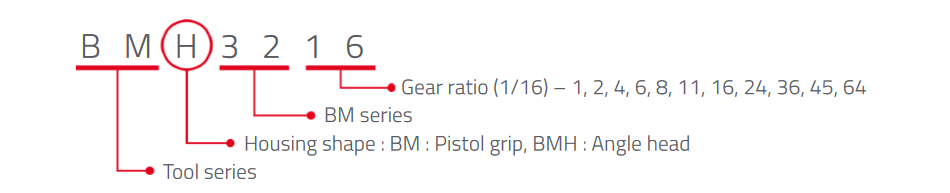

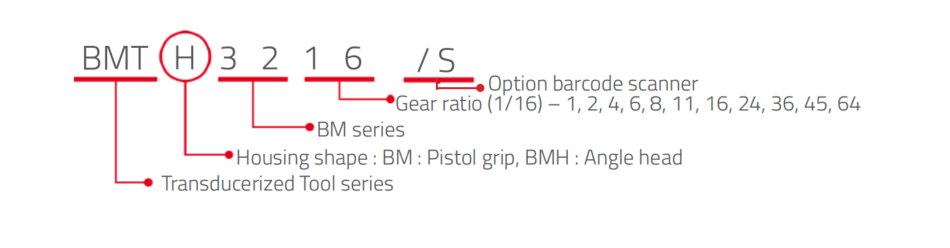

Which model to choose?

Current control or integrated torque and angle transducer?

These DC screwdrivers are the most advanced tool on the market.

Whereas the BM screwdrivers provide you with an excellent repeatabilty thanks to its current control technolgy and angle encoders the BMT series enjoys in addition a built-in torque transducer to measure precisely and display instantly the actual torque.

They accurately measure the applied torque of each tightening point and display it directly on the tool.

This intelligent control guarantees high assembly precision and eliminates the risk of error: the real torque value is measured at each tightening and a precise speed regulation in closed loop is ensured thanks to the integrated digital angle encoder.

- Torque target accuracy >= +/- 7% within a capability Cmk >1.67

- Average repeatability of +/- 2%

- Real torque monitoring

- Not sensitive to joint type

Specifications

|

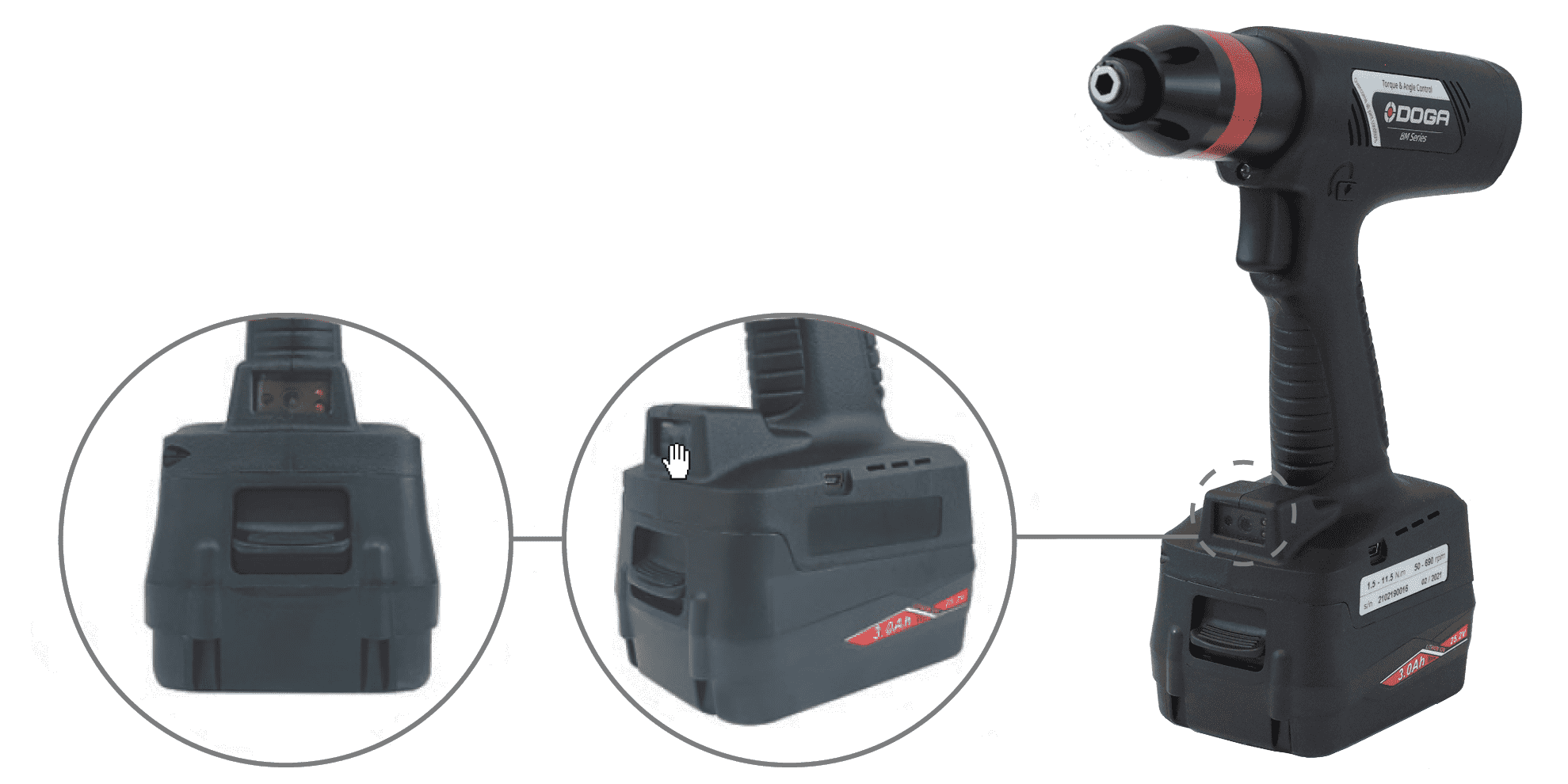

Electric power

|

DC25.2V, Lithium ion battery

|

|

Motor

|

Swiss DC servo motor

|

|

Torque repeatability

|

+/- 3%

|

|

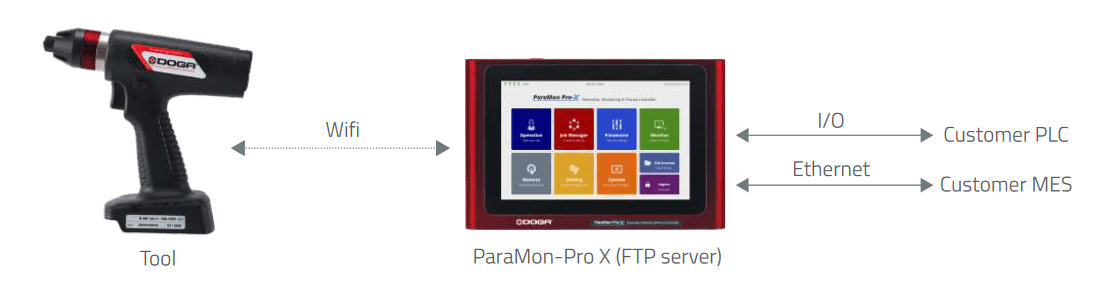

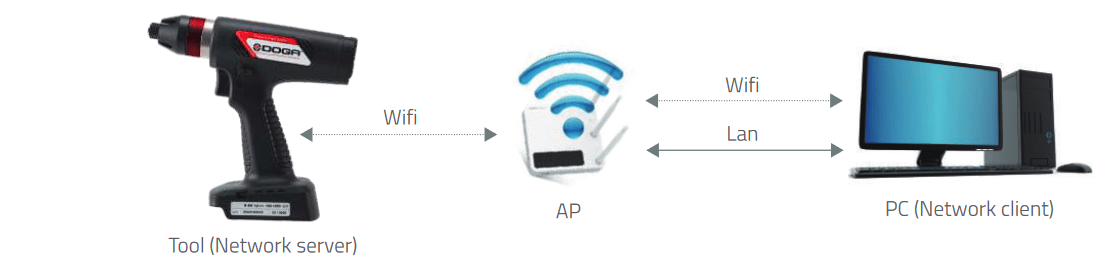

Wifi

|

IEEE 802.11a/b/g/n 2.4GHz & 5GHz dual band

|

|

Speed

|

Auto speed by torque setting

|

|

Data memory

|

65,000 data

|

|

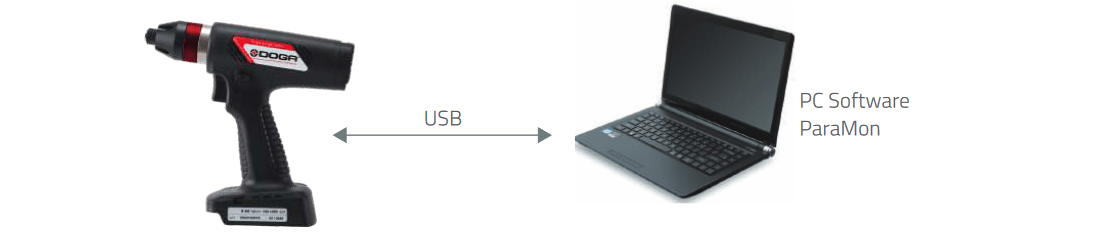

USB

|

Micro USB port

|

|

Display

|

1.29” AMOLED color display

|

|

No. of preset

|

15 preset programing by USB or Wifi

|

Connection

- Initial network and parameter setting, data monitoring

- Data download from the internal memory (max 65 000)

- Tool firmware update

- Connect up to 8 BM tools

- Error-proofing through assembly sequencing and process monitoring

- Simple and user friendly sequence programming interface

- 2 x USB 2.0 ports - Bar code scanning (optional)

- HDMI port for display extension

- Parameter setting, data monitoring on PC with ParMon or custom software

- Protocols are open for programing the custom software

ParaMon III software

|

|

ParaMon III is a PC software for network tools management, setup and backup via an integrated database. This free software provides easy parameter setting, data monitoring & analysis compatible for all torque and angle control DC tools as MD, MDT, BM, BMT series and ParaMon-Pro X controller.

|

Download the ParaMon III software >