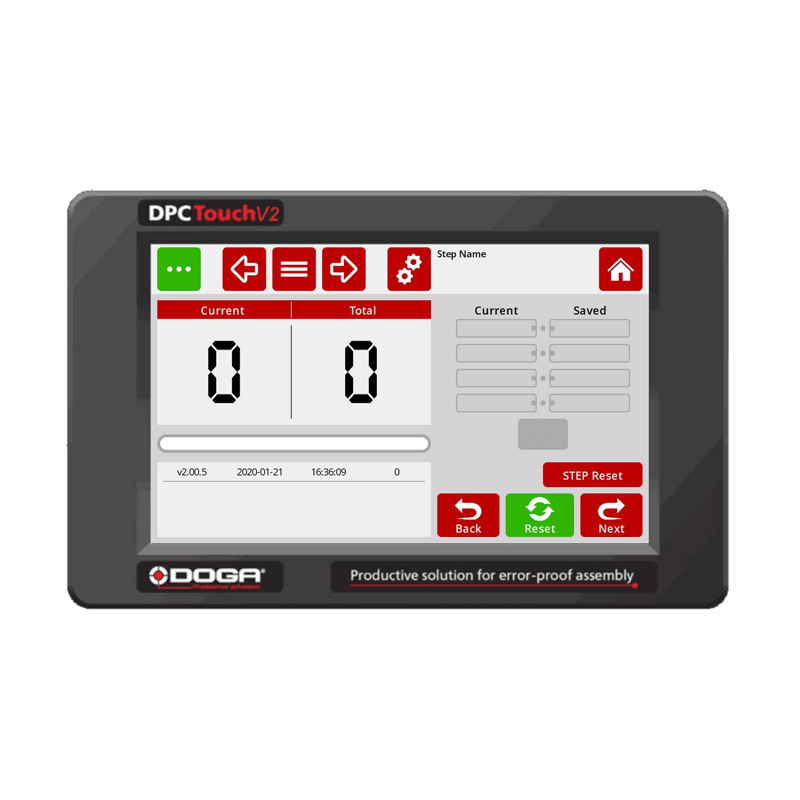

DPC Touch: sequencing and process monitoring interface

DPC Touch: sequencing and process monitoring interface

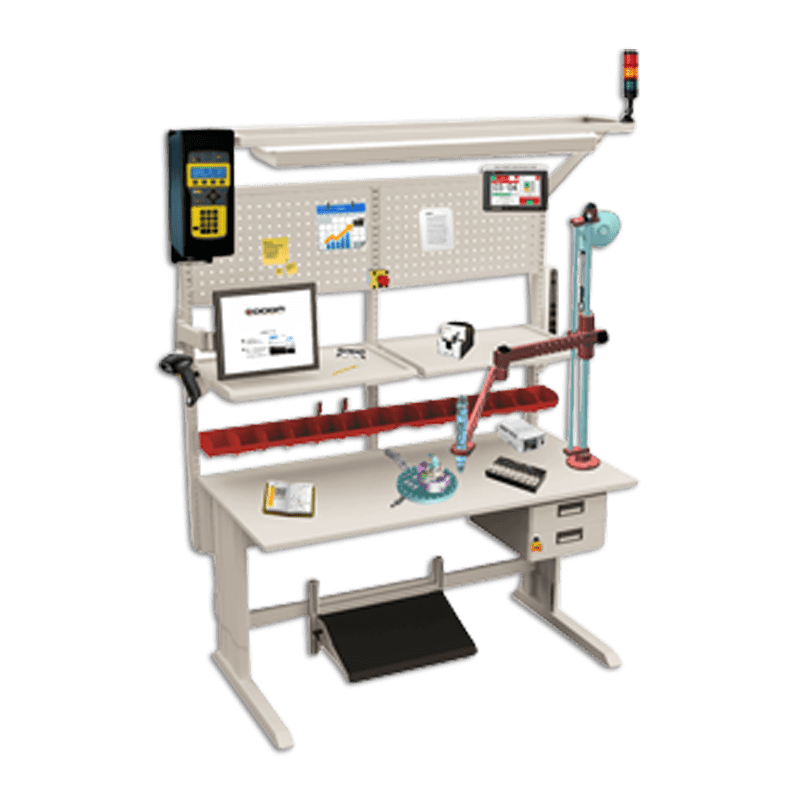

To guarantee quality production, an assembly process needs to be counted, checked, ordered and displayed. Our sequence management tools are specially designed to fulfil all applications. The DPC Touch, our assembly sequence management interface, is the ideal tool for stand-alone work stations.

Benefits

- Process and instructions can be viewed by image or text

- Tolerance settings for every assembly point

- Communication with a PLC

- Cycle called by a bar code reader

- Compatible with screw feeding

- 80 steps per job

- 12 assignable inputs / outputs

- 4 position sensors managed on the positioning arms

Product description

A genuine orchestral conductor, the DPC Touch can count, order, check and display an assembly process. Compatible with most assembly tools, it is the ideal sequencing tool for stand-alone work stations. Connected to our torque reaction arms, it will guarantee you optimum quality and traceability.

Videos

Associated services

Installation and commissioning are strongly recommended for the control and correct use of assembly technology and process control. Please feel free to contact us.

Our technician will train users so that they are perfectly autonomous. He will indicate the best measures to take to be able to make the modifications following changes to your applications yourselves.

If technical assistance is needed, please contact us.

Our technician will remotely troubleshoot the cause of the failure and will indicate the best measures to take to carry out the repair yourself.

Resources

3Plan

1Commercial documentation

Documentation - DPC Touch V2, sequencing and process monitoring interface - DOC.60356

- Technical features

- Benefits

- Compact "all in one" interface

- Positioning control

- Sequencing and process monitoring

- Applications

- References and accessories

- Our services

4Software

V2 - DPC Touch Remote software

Software to install on your computer to access to DPC Touch V2 in Modbus TCP/IP.

File: DPCRcs_v1.00.6_20201217

V2 - DPC Touch V2 Firmware

File: DPCTouch_v2.02.2_20220829.bin

Firmware upgrade procedure:

1. Power OFF the controller and take out the SD card

2. Create "update" folder on the SD card

3. Copy firmware file to the "update" folder

4. Insert SD card into the controller and power ON

5. Track update progress up to 100%

6. Power OFF the controller, take out the SD card and delete the "update" folder

V2 - Image template adapted to the screen format of the DPC Touch - DOC.40456

This PowerPoint template can be used for fast and easy creation of graphical messages for DPC Touch V2.

These slides are specially formatted to match with the DPC Touch V2 screen size (800 x 480 px)

V1 - DPC Touch firmware – 4-1290016

File: DPC_Touch v0.7.4 20201016

Firmware upgrade procedure (for controllers with firmware v.0.7.0 and later):

1. Power OFF the controller and take out the SD card

2. Create "update" folder on the SD card

3. Copy firmware file to the "update" folder

4. Insert SD card into the controller and power ON

5. Wait for approximately 30 seconds until the controller is booted

6. Power OFF the controller, take out the SD card and delete the "update" folder

V1 - DPC Touch firmware upgrade BootloaderDPC_v1.0.5_20181004 – 4-1290016

ATTENTION! Controllers with firmware v0.6.9 and earlier have to be firstly upgraded through RS232 with this file. See the firmware upgrade manual. Once controller is upgraded, the new firmware can be uploaded via SD card

Download the file in zipV1 - DPC Touch firmware upgrade manual – MU.60247

- Hardware and software required for upgrade

- Procedure

2Technical documentation

V2 - User manual sequencing and process monitoring interface DPC Touch V2 - DOC.60352

- Informations

- Starting up

- Settings

- Use

- Maintenance

- Safety

- Standards

- Appendices

V1 - DPC Touch instructions manual – MU.60290

1- Specifications

2- Hardware

3- Getting started

4- Main menu

5- Job manager

6- New job creation

7- Settings

8- Operating mode

9- Electrical wiring

10- Trouble shooting

5Cases of application

Application sheet - Controlled assembly station - DOC.60397

Design and manufacturing of complete station equipped with HMI (DPC Touch) and presence sensor. Assembly of electric components of a charging plug unit for electric vehicle.

Download the file in pdf

Application sheet - High torque fastening on mobile aerial lift - DOC.60319

Assembly of aerial lift components at 225 Nm and 66 Nm without reaction bar. Operator visual guidance required during assembly operations.

Download the file in pdf

Fiche d'application - Montage insert Helicoil® - FA.40621

Pose d'inserts Helicoil® avec comptage et positionnement.

Download the file in pdfPoste de travail équipé - FA.40995

Assemblage d'équipements électroniques complexes selon une séquence définie avec appel de cycle de vissage et contrôle de position.

Download the file in pdf