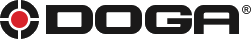

DMA and BST 300 – Auto advanced automatic screw feeding systems

DMA and BST 300 – Auto advanced automatic screw feeding systems

The auto advanced screw feeding systems are extremely robust, totally comfortable to use, silent and vibration-free. By repeatedly delivering each screw to the assembly tool head, the automatic screw feeding system provides significant time savings, in particular on the operator cycle.

Benefits

- Faster cycle time

- No adjustments required

- Robust design

- Silent operation completely free of vibrations

- Avoids the contact of the tip with the part

Product description

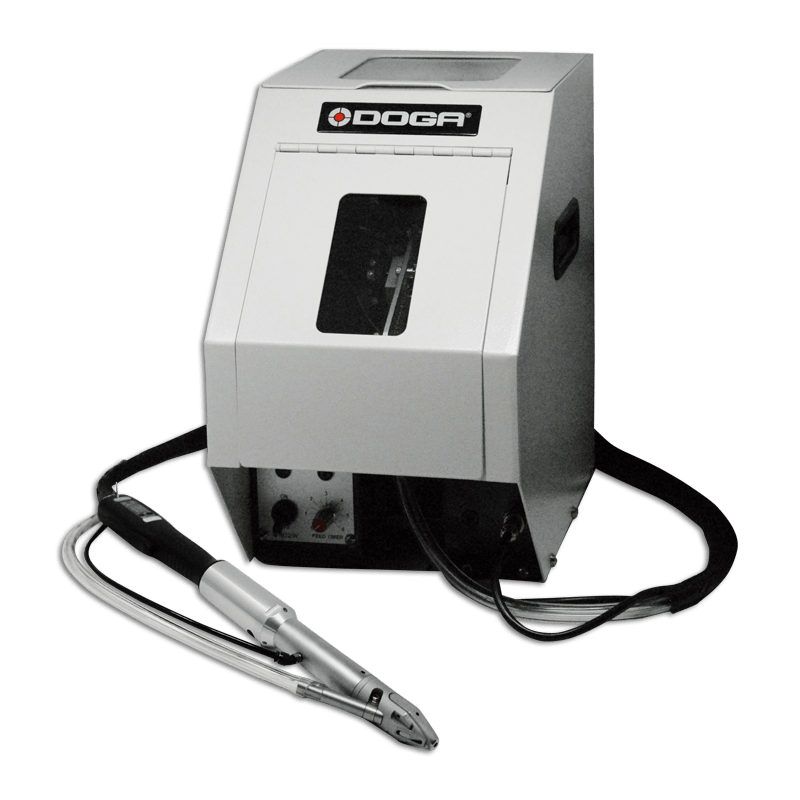

The DMA automatic screw feeder includes a hollow rocker arm type feeder that selects and directs the screws before transferring them to a gravity rail down to the separator.

From there, a screw is blown into the pipe to the assembly head each time the screwdriver sends a request. In parallel, a new screw is separated and transported through the blow tube.

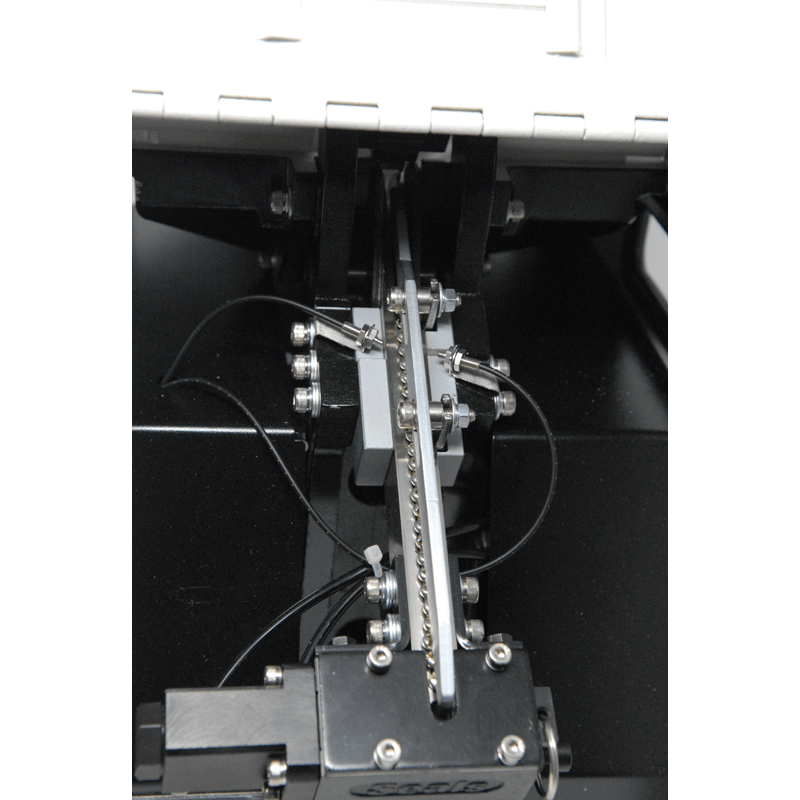

The screw is kept above the screw head mandrel by mechanical shutters to make it easier to pin it onto the part.

The continuous pressure of the operator on the screwdriver start control causes the pneumatic telescope to push the screwdriver bit into contact with the screw and follow it through the complete assembly into the part.

Screw compatibility:

The accepted screw dimensions vary from a body diameter of 2.3 to 6 mm and a body length of up to 22 mm.

The total head diameter / length ratio should ideally be 1.5.

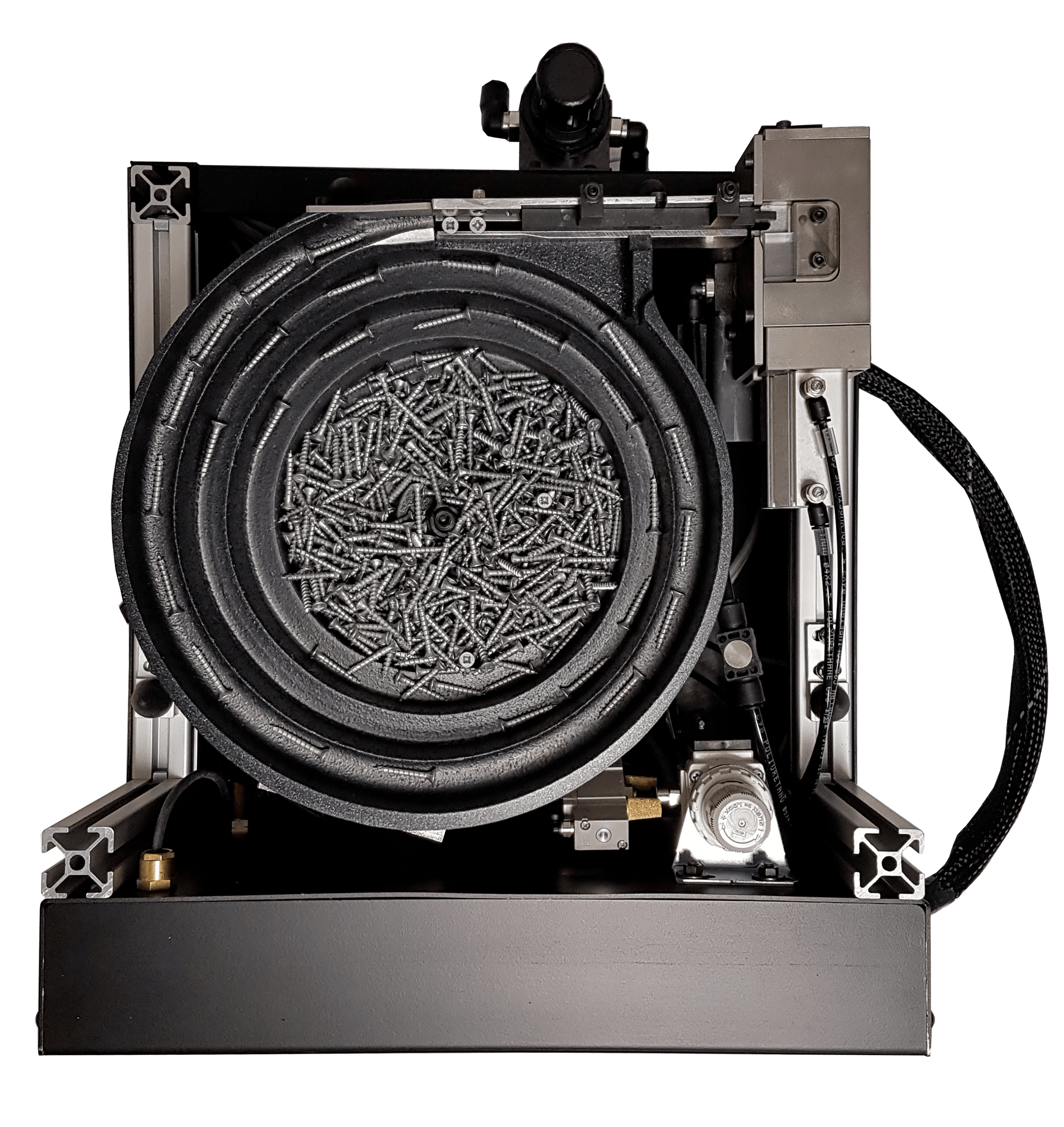

For smaller, larger or longer screw dimensions, the rocker arm system can be replaced by a vibrating bowl (feasibility study needed).

Operating mode :

The BSF 300 automatic screw feeder incorporate a vibratory bowl feeder that selects and orients the screws before transferring them to a rail to the separator.

Before transferring them on a rail to the separator. From there, a screw is blown through the pipe to the nozzle.

From there, a screw is blown through the pipe to the screw nose at each request sent by the tightening machine.

At the same time, a new screw is separated and fed into the blow tube.

The screw is kept protruding into the screw nose at the jaws by advancing the tightening bit to an intermediate stroke to facilitate pinning to the workpiece.

The self-advancing tool is capable of transmitting torques up to 16 Nm.

Screw compatibility:

The screw feeder is a vibrating bowl feeder, allowing the feeding of screws with a body length of up to 30 mm and a head diameter of up to 13 mm.

Videos

Associated services

Our after-sales department can install and assist during commissioning on your site.

Resources

Automatic screwfeeding systems - DMS / DMA / BSF 300 / DMM / DA-100 series - DOC.60315

- Telescopic automatic screwfeeding system - DMS serie

- Auto advanced automatic screwfeeding system - DMA serie and BSF 300 serie

- Automatic screwfeeding system magnetic - DMM serie

- Automatic screwfeeding system for automation - DA-100 serie and BSF 300 A serie

- Applications