CELPRO | Traceabilty and process control

CELPRO | Traceabilty and process control

Resources

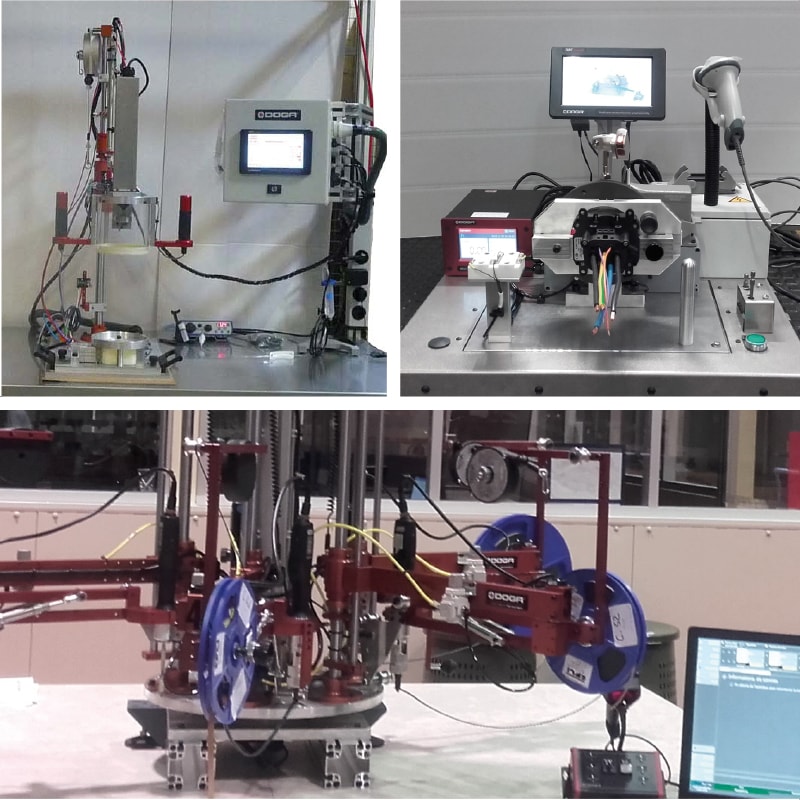

Application sheet - 3 spindles tightening workstation - DOC.60421

Workstation equipped with a fixed center distance 3 spindles fastening head. Target torque 46 Nm.

3 Stanley QBE-Advanced tightening units & axial screwdriver E34LB1-100 & specific mechanism.

Application sheet - 5 stations carousel to install helicoil inserts - DOC.60417

Installation of helicoils on electric components in the military industry.

Download the file in pdf

Application sheet - Box assembly station on electronic board - DOC.60403

Controlled assembly of electronic boxes on a board without forgetting screws with printing at the end of the sequence of a report label.

Improved ergonomics for assembly operations.

Cycle time saving on the tightening operation.

Application sheet - Complete tightening workstation with in line transducerized tools - DOC.60422

Accurate tightening in vertical and horizontal position of a loom angle.

Download the file in pdf

Application sheet - Controlled assembly station - DOC.60397

Design and manufacturing of complete station equipped with HMI (DPC Touch) and presence sensor. Assembly of electric components of a charging plug unit for electric vehicle.

Download the file in pdf

Application sheet - DAMPER mounting station - DOC.60363

Station for mounting of a plastic DAMPER element on a part in an aluminum casing.

Ensure the DAMPER assembly directly in the final packaging with torque at 10 Nm with pre-tightening at 5 Nm and checking that the 4 parts have been correctly assembled.

Application sheet - Metrology board - DOC.60424

Metrology board dedicated to the control of tightening tools used for the maintenance of military machines in workshops and in operations.

Download the file in pdf

Application sheet - Multi torque tightening workstation - DOC.60410

To tighten M6 to M12 screws at various torques from 38,4 to 210 Nm.

Download the file in pdf

Application sheet - Srewfeeding unit - DOC.60395

Bollhöff screw feeding unit to dispense a preset number of screws on assembly station of electric vehicle propulsion unit. To be able to guarantee that the operator get the preset number of screw and to avoid risk of screw loss in the electric motor.

Download the file in pdf

Application sheet - Tightening workstation of firing pin - DOC.60412

Tightening of firing pins on pyrotechnic grenade at 2 Nm.

Download the file in pdf