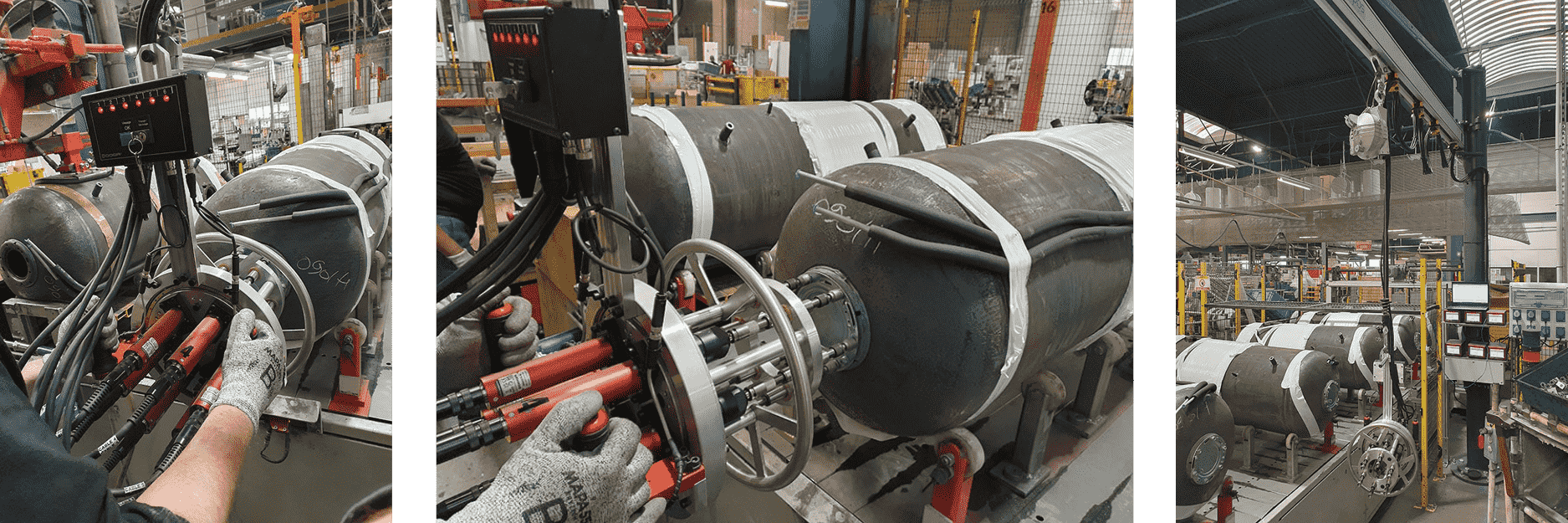

Application case: multi-spindle tightening solution for hot water cylinder. 6 screws at 20 Nm

Our customer wanted to increase its productivity, manufacturing quality and improve ergonomics of the operators.

Before choosing DOGA solution, the customer was encountering quality and reliability issues linked to the usage of angle head pneumatic screwdriver with non-stable air network.

This manufacturing process led to uncertain delivered torque, NOK tightenings and leaks.

DOGA | ASSEMBLY TECHNOLOGY GLOBAL SOLUTION

To answer these productivity, quality, and ergonomics needs, DOGA provided a global solution:

➡ 6 torque and angle controlled spindles MDA3236

➡ Current control technology ensuring correct torque reached and fastening OK

➡ Tailored programming to ensure a proper start and optimise cycle time

➡ Tailored structure to hold the 6 spindles according to the screws position

➡ This structure is mounted on a pole with a 125 kg capacity balancer

➡ Integration of a process monitoring box to provide direct feedback to the operator

BENEFITS

✔ Productivity

o Cycle time is optimized of more than 30%

o 6 tightenings simultaneously without manual rework needed

✔ Quality

o Poka-Yoke system allowing operator to detect any NOK and ensure a 0 defect final assembly

o No more risk of defect thanks to increase accuracy with current control technology

✔ Ergonomics

o Torque reaction erased by the multi-spindle structure

o Weight of the structure managed by the balancer

o Total freedom of movement thanks to this integrated all in one device

> Consult additional industrial integration projects examples

> Contact us to initiate your tightening solution project